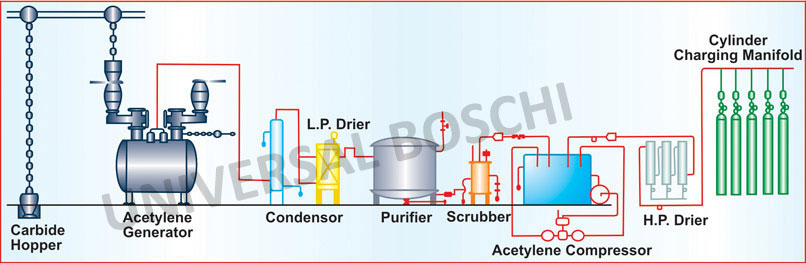

Acetylene plant is fabricated with high quality materials and using the latest technology. Acetylene gas is generated as a result of reaction between calcium carbide and water.

-

acetylene gas plantwe offer high quality acetylene gas plant for industrial uses.

acetylene gas plantwe offer high quality acetylene gas plant for industrial uses.